TL;DR

-

Yacht costs increase when small issues turn into big repairs, so the smartest owners start by preventing surprises before they happen.

-

That shift gets easier once you use tools like DockMaster to schedule service, track parts, and streamline jobs.

-

Real-time diagnostics make it even better by catching early failures, supported by systems that already help boost fulfillment accuracy by 20%.

-

All of this works together to cut maintenance costs, avoid rush fixes, and keep every trip smoother, safer, and far more predictable.

Yacht ownership feels like pure freedom. Sun on the deck. Wind teasing the water. Engines humming with quiet confidence. However, this thrill of buying a vessel is quickly matched by the reality of yearly ownership and maintenance costs. What many don’t realize is that these expenses often rise due to avoidable issues, including reactive repairs, unclear service schedules, rushed part replacements, or simply choosing storage and mooring options that cost more than they should.

Still, you can trim those expenses faster than you expect. You just need a few clever moves. That’s why more yacht owners now rely on smarter planning and streamlined maintenance practices to keep expenses in check.

In this guide, we’ll walk you through practical ways to reduce yacht maintenance costs, from choosing the right mooring and exploring financing options to adopting strategic upkeep practices and using the six cost-saving methods below.

How to Reduce Yacht Maintenance Cost: 6 Expert Strategies

Reduce yacht maintenance costs with these 6 practical tips that help you maintain quality, prevent expensive repairs, and protect your investment.

1. Preventive maintenance scheduling

If you try to manage your maintenance schedule in your head or on a document, you end up with missed services, unexpected failures, and yacht maintenance costs that increase faster than you expect. One skipped oil change turns into engine trouble. One ignored inspection becomes a weekend stuck at the dock instead of out on the water.

When you use smart preventive scheduling, you set up every important task before anything goes wrong. It keeps repairs cheaper, downtime shorter, and your trips far smoother. Think of it as one of the easiest yachting maintenance tips you can adopt. DockMaster’s service scheduler helps you map out everything on a clear, interactive calendar. As a result, you can drag and drop work weeks or months ahead so you never struggle at the last minute again.

With preventive scheduling, your team can:

-

Assign technicians to upcoming jobs

-

Block out dock space and service bays as needed

-

Set automated reminders for upcoming service dates

-

View full vessel maintenance history before scheduling

-

Prepare the necessary parts and labor in advance

This simple habit helps you avoid surprise breakdowns and keeps your boating plans delightfully predictable.

Interesting read*: Efficient Infrastructure Maintenance Tracking Using DockMaster*

2. Smart inventory use

If you have ever needed a part right before a trip and discovered the shelf sitting empty, you know how fast your yacht maintenance costs can shoot up. One missing filter or a delayed fuel delivery can turn a simple fix into an expensive scramble. When you keep your inventory under control, you avoid those stressful surprises and keep your yacht ready whenever you feel like heading out.

DockMaster gives you an easy way to track every part, fuel refills, and even the smallest items you rely on. Here’s what you can do:

-

Set your minimum and maximum stock levels so you always know when to reorder

-

Watch real-time inventory updates and stop estimating what you actually have

-

Review detailed reports to spot fast-moving items, slow movers, and hidden budget drains

-

Use barcode labels to keep shelves tidy and reduce tracking errors

-

Access integrated parts catalogs to track usage accurately and avoid mix-ups

-

Keep everything clear, organized, and ready whenever a job comes in

For example, before switching to DockMaster, Atlantic Boats handled inventory manually. That created repair delays and constant stockouts. After adopting the platform, they forecasted demand more accurately, automated reordering, avoided parts shortages, reduced downtime, and helped technicians finish jobs faster without drowning in admin work.

As Jason Lindstrom, Marine Store Manager at Atlantic Boats, shared:

“For businesses still running their operations on pen and paper, they don’t know what they’re missing out on. DockMaster brings so much more ease and efficiency to marina businesses. I still keep paper and notes out of habit, but at the same time, I really don’t have to, because 99% of the transactions and correspondence is stored in the software.”

3. Digital work order management

Think about having a single system that lets you track every customer, vessel, and job without confusion or missing details. That is exactly what DockMaster does. You can create work orders directly from approved estimates, eliminating duplicate data entry and saving hours of manual work. Each work order shows all the details you need, including the customer, the vessel, the requested service, and the parts or labor required.

When special-order parts are involved, DockMaster automatically tracks them. Your team always knows what is on the way and when it will arrive. The service monitor gives everyone, from office staff to dock technicians, a real-time view of every job. You can see what is active, waiting for parts, or ready to bill. Miscommunications vanish, and paperwork no longer gets lost.

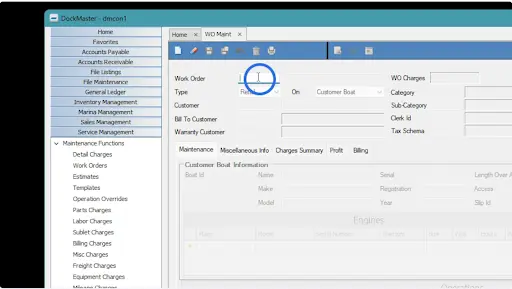

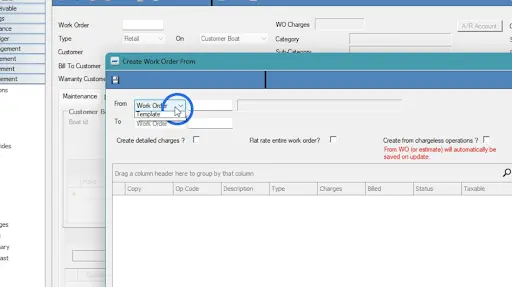

To create a work order in DockMaster:

- Go to Service Management → Maintenance Functions → Work Orders

- Create a new one by typing N, clicking the blank paper icon, or entering a new number. Or right-click in the ID field and select Create WO from F9 to generate from an estimate, template, or existing work order. Use F6 or \ to search if needed

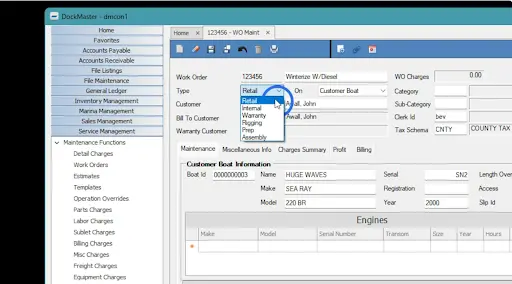

- Choose from Retail, Internal, Warranty, Prep/Rigging, or Assembly, depending on billing and operations

-

Fill required fields, including customer and billing info, warranty status, clerk ID, category, creation and due dates, and estimated start and completion dates

-

Select an existing vessel or enter a new one for one-off cases

-

Use the operation grid to add services, update labor and parts, insert opcodes, or adjust pricing

-

Review tabs for full context:

-

Miscellaneous info: Add comments or custom fields

-

Charges summary & profit: See breakdowns and margins

-

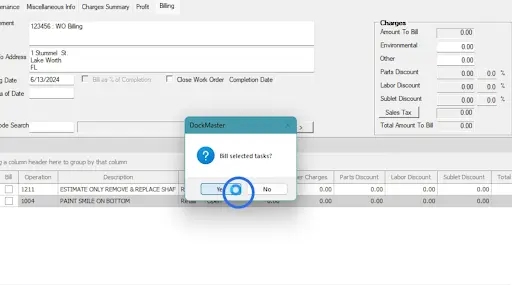

Billing: Apply discounts, handle partial or complete billing, and close the job

- Save the work order and confirm to complete billing or invoicing

Because everything updates in real time, you can keep customers informed throughout the job, boosting trust and satisfaction. Clear, detailed estimates eliminate surprises, and you can quote flat rates or hourly fees without stress. Streamlining work orders with DockMaster reduces costly errors, prevents delays, and keeps your workflow smooth, saving you time, money, and headaches while keeping your customers happy.

4. Using real-time diagnostics & telematics

Real-time diagnostics transform maintenance into data-driven action. Sensors and telematics systems monitor the yacht’s engines, batteries, fuel flow, temperatures, vibration levels, and electrical health. These tools catch early signs of failure that no human could notice without advanced instruments.

In fact, robotic systems are now responsible for a 20% increase in order fulfillment and a 15% reduction in errors. For owners, real-time diagnostics reduce stress. Trips feel safer because the yacht communicates continuously. For service centers, telematics eliminates assumptions. This readiness increases job accuracy, shortens service time, and reduces labor cost.

DockMaster integrates diagnostic data into service workflows. Here’s what using real-time diagnostics looks like in action:

-

Technicians update job status and track hours on DockMaster Mobile while they work

-

Front-desk staff check guest history before assigning slips or sending reminders

-

Managers review dashboards weekly to tweak staffing, schedule repairs, or plan promotions

Over time, this approach turns data into a habit. Your team stops reacting to problems and starts anticipating needs, making smarter decisions with clarity and speed.

5. Better vendor & parts management

Ever ordered a part only to wait days for it to arrive? Without a structured vendor management system, teams often overspend or wait too long for critical parts.

When you manage vendors and parts effectively, you keep repairs on track, reduce downtime, and ensure every job finishes on time. Here’s how DockMaster helps:

-

Track all parts in one system, so you know what you have and what you need

-

Monitor vendors for delivery speed and reliability

-

Set reorder points to avoid running out at the worst time

-

Review past orders to find trends and improve budgeting

-

Coordinate with your team so parts are ready before the job starts

6. Leveraging mobile marine apps

Technicians perform best when they can document work fast and accurately at the point of service. Mobile marine apps give them that power. Instead of walking back and forth to the office, writing notes by hand, or trying to remember details at the end of the day, technicians log information instantly on a mobile device.

DockMaster’s mobile access keeps your team connected and productive wherever they are, helping you control yacht maintenance costs and get more done with less hassle. With DockMaster Mobile, your technicians can:

-

Check job details and schedules from any device so they know exactly what to tackle next

-

Update work order progress in real time to keep everyone on the same page

-

Log hours and add service notes on the go, avoiding missed details

-

Capture and upload photos or videos of repairs to document work accurately

-

Share visual updates with customers to boost transparency and trust

The result is less rework, stronger accuracy, and smoother coordination.

Also read: How Technology Is Changing The Standards Of Marine Operations: 10 Transformative Trends

Common Pain Points These Strategies Solve

These six strategies directly address the biggest challenges that owners and marine service centers face today, such as:

-

Rising parts and labor costs that strain every budget

-

Seasonal spikes in demand that overwhelm teams

-

Missed maintenance steps that create avoidable failures

-

Poor documentation that leads to confusion and costly rework

-

Inefficient workflows that slow down service and increase frustration

As a result, costs stay under control, workflows remain organized, communication improves, and every part of the maintenance ecosystem works together to keep the yacht performing at its best.

Reduce Your Yacht Maintenance Costs With DockMaster

If rising service expenses, unpredictable failures, missed documentation, or seasonal chaos feel too familiar, this is the perfect moment to explore stronger systems. DockMaster’s suite of visual marine management tools helps every team manage yacht maintenance more effectively, stay organized, and cut long-term costs without cutting quality.

The platform provides clear visibility into scheduling, inventory, customer data, diagnostics, documentation, labor usage, and customer communication. The entire maintenance process transforms into a coordinated system that protects both the vessel and the budget.

Explore DockMaster today and support a smoother, more cost-efficient yachting life.